fernando meneses

5_3D scanning and printing

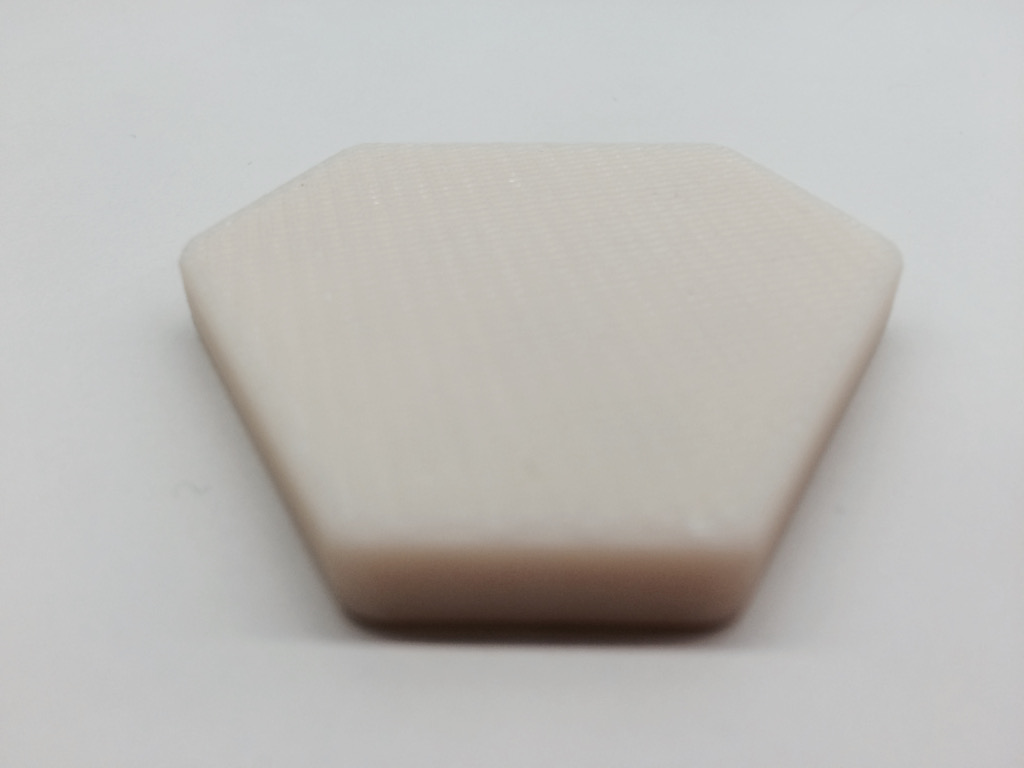

_design and 3D print an object (small, few cm) that could not be made subtractively

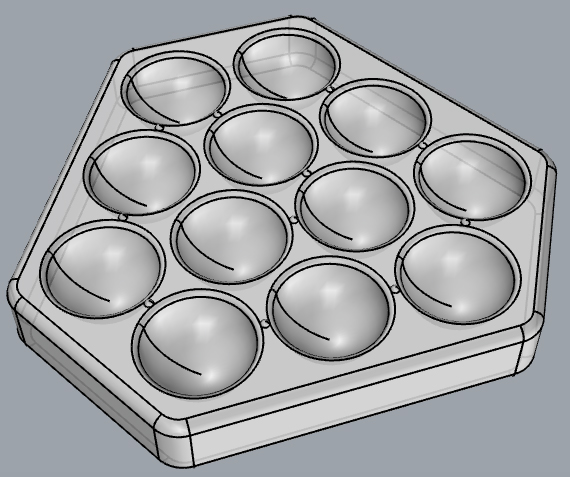

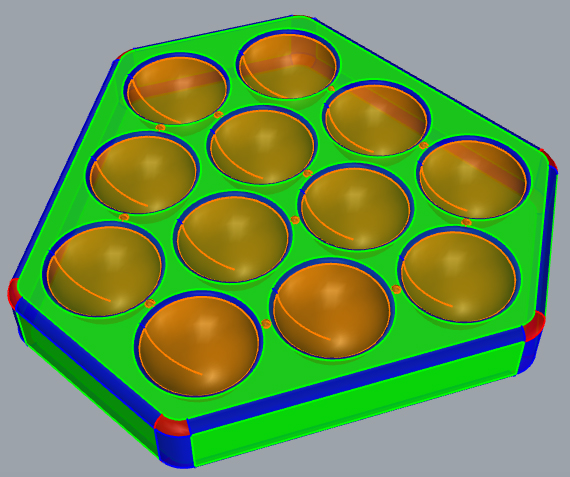

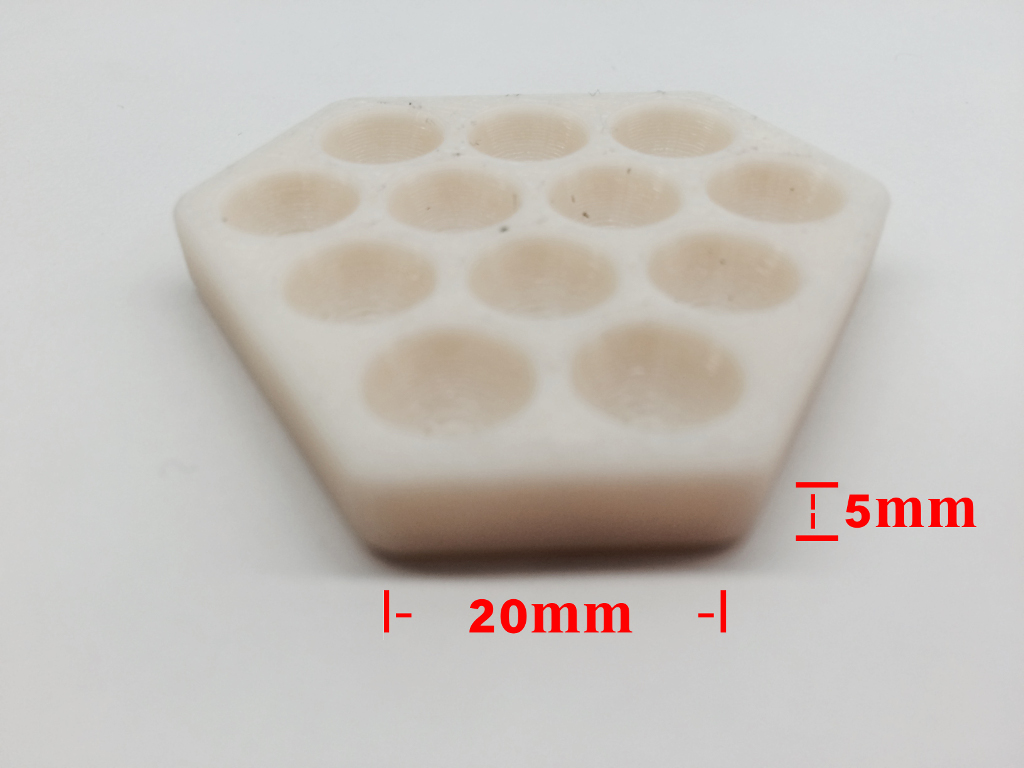

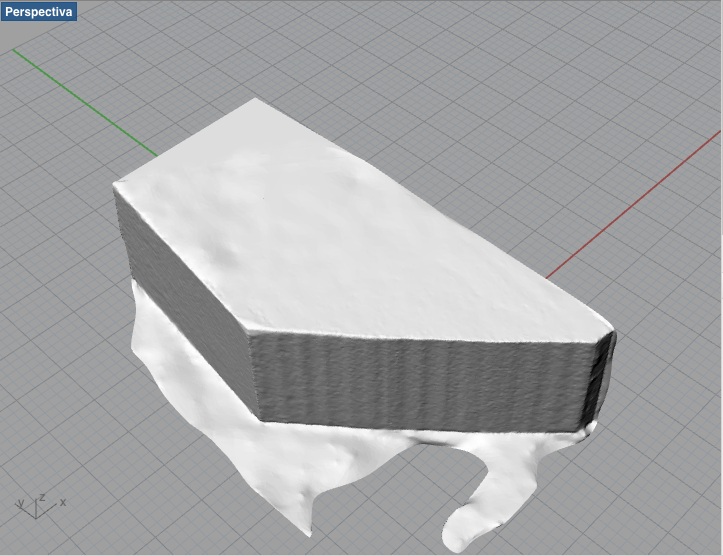

For this activity I will present a part of the final project (the final project is a device that helps to cultivate and identify bacteria). It is a part that has to support the cultivation of bacteria with 12 different media (enteropluri).

The main qualities of the piece are: should not have any curves and is very small, so the workpiece shopkeeper on all sides, if we do by subtractively, by this and by the size, I have the intention of making an additive method as 3D printing.

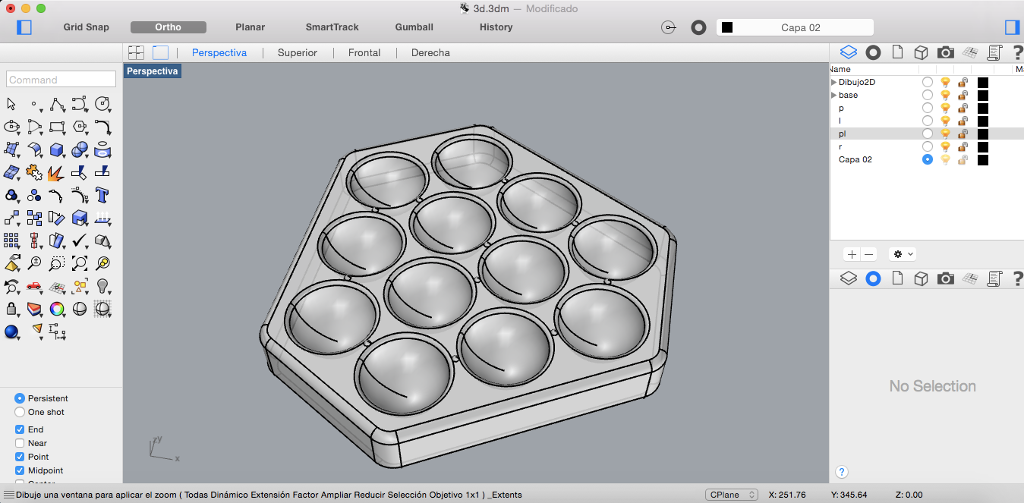

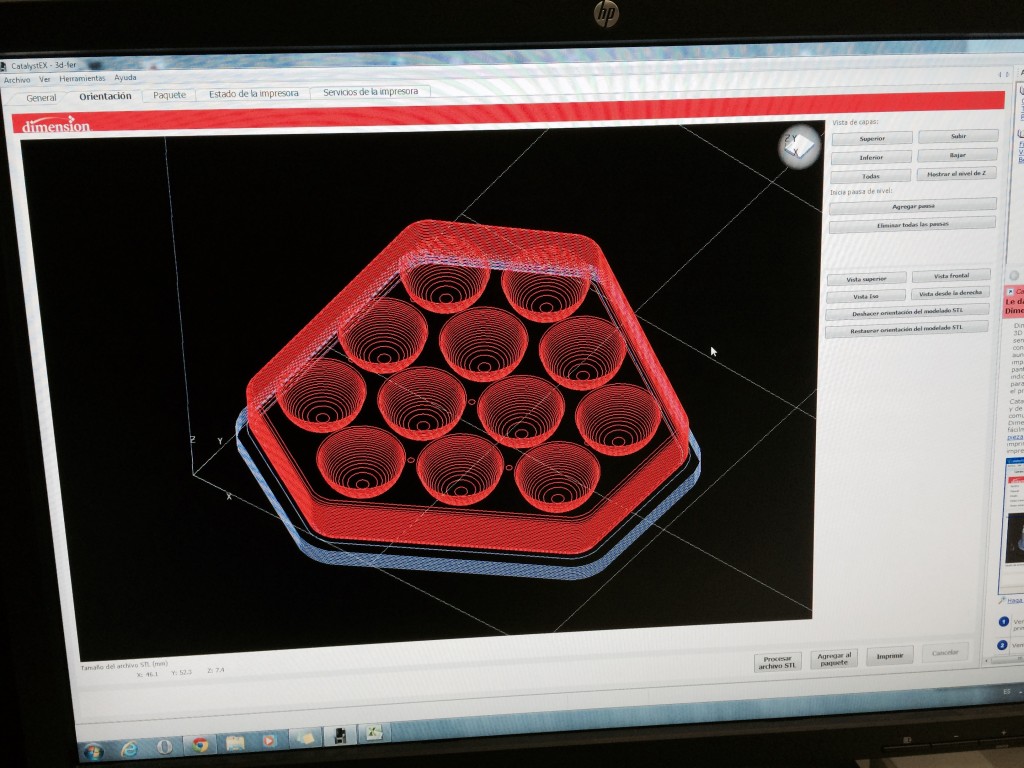

Here a screenshot, the design in rhino.

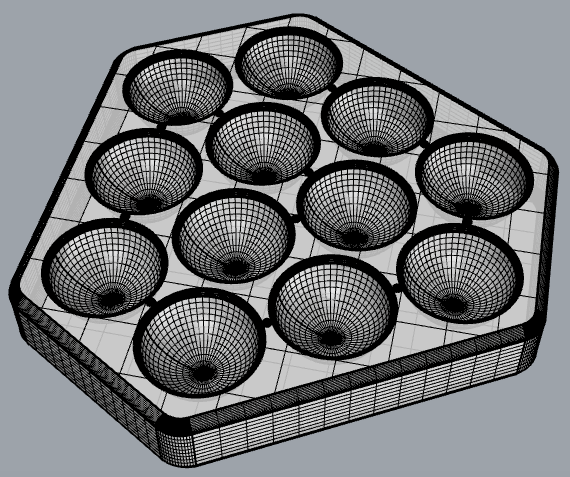

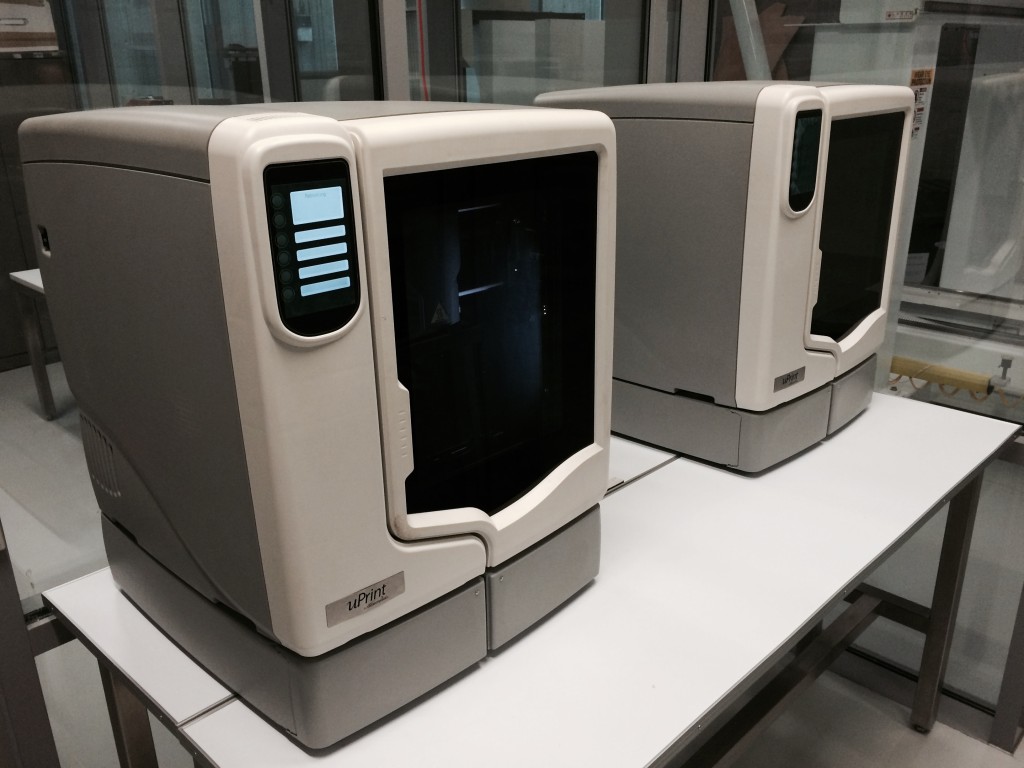

After modeling, stl is exported, and in our case the print on a uPrint, here are some pictures of the process.

_3D scan an object (and optionally print it)

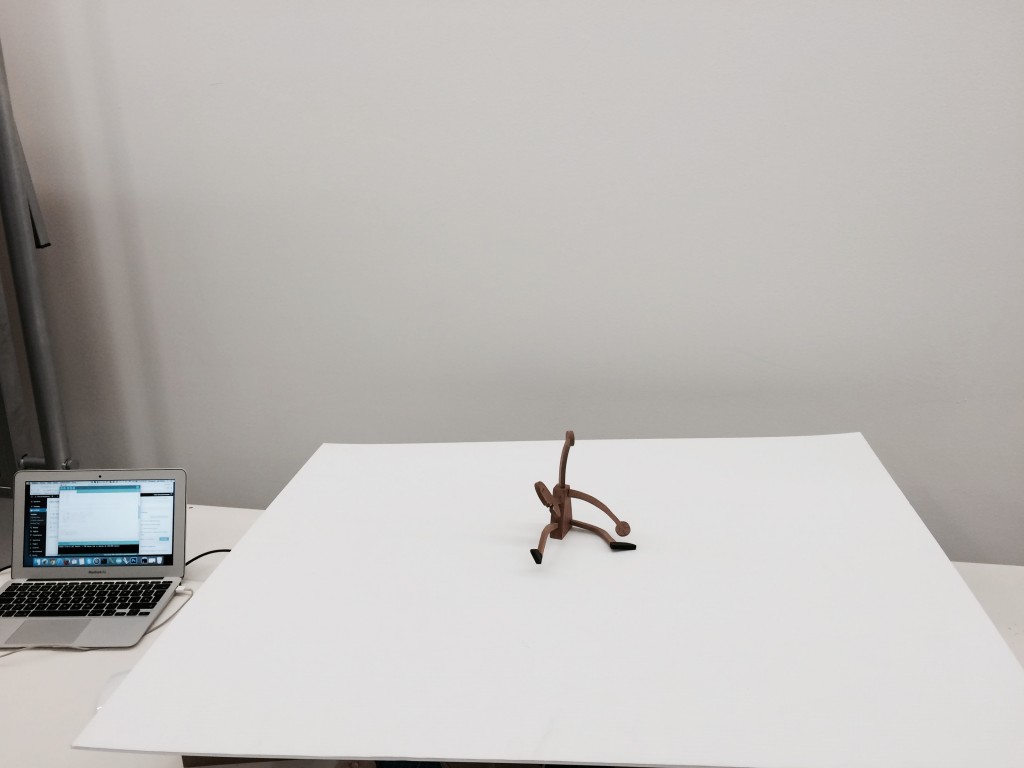

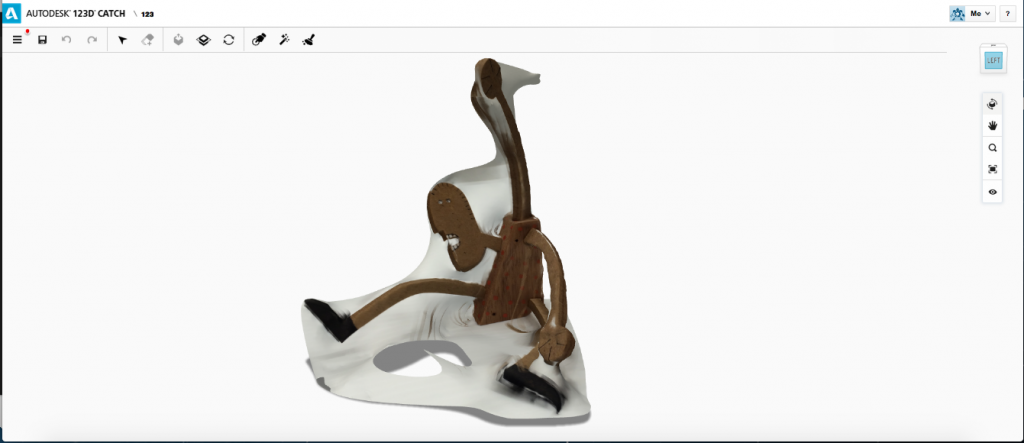

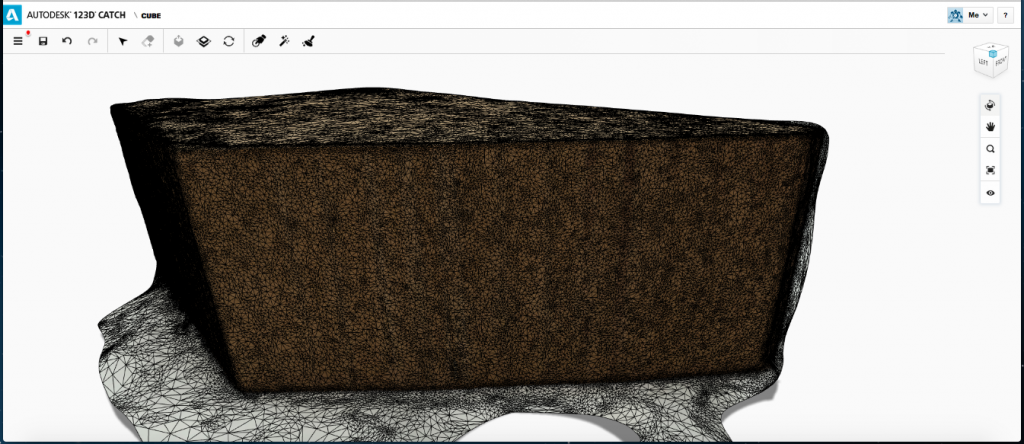

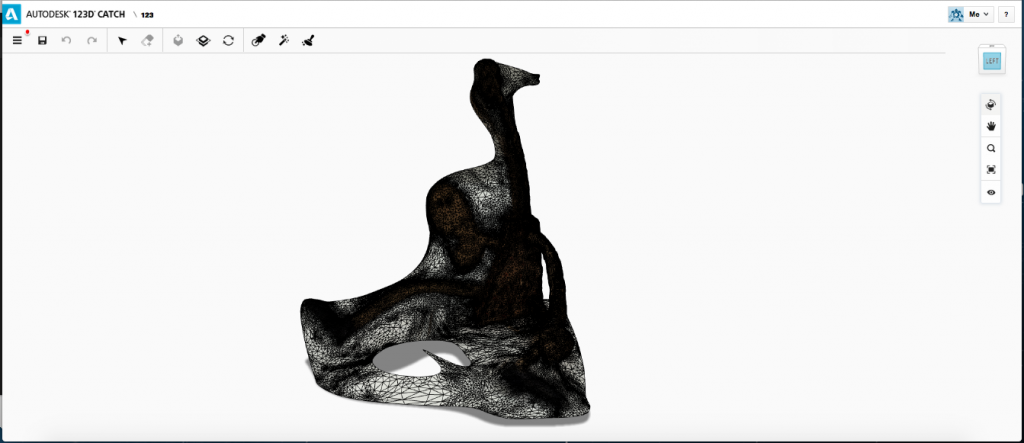

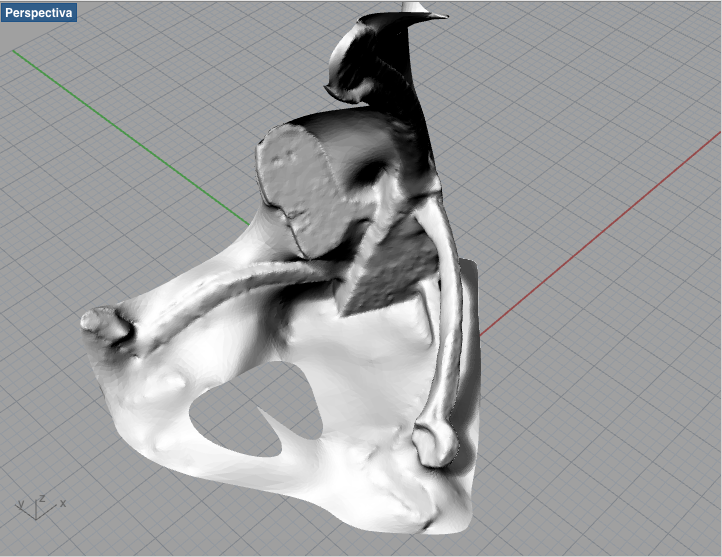

For the activity 3D, I will use 123D Catch scanner, select two objects, one simple and complex.

I used a rotating basis to control the movement of the object.

_conclusions

After the great success of 3D printing in recent years, it would be superfluous to say that knowledge of 3D modeling is essential, on the other hand it is not only matter of modeling, there are options such as scanning to capture the physical world, here the scanner 3D is also very important.

In this activity try to control geometry using different geometric topology, but in the end to send it to print was only one 3d stl, this makes me think; A few years ago scanning and 3D modeling was a science of very few, today is surprisingly affordable to almost everyone.

I think beyond 3D modeling techniques, the success of 3d printing, makes me think of the democratization of these technologies, and I wonder if one day all will be able to develop our own microcontrollers and not only the PCB.

_files

Update: in the activity of machine design, design a prototype of a 3D scanner.. >>>

_

Original source: http://academy.cba.mit.edu/classes/scanning_printing/index.html

Contact: fernando.meneses@udem.edu / fernandomeneses@nodolab.com / f / in / g+ / b / v / mx / w